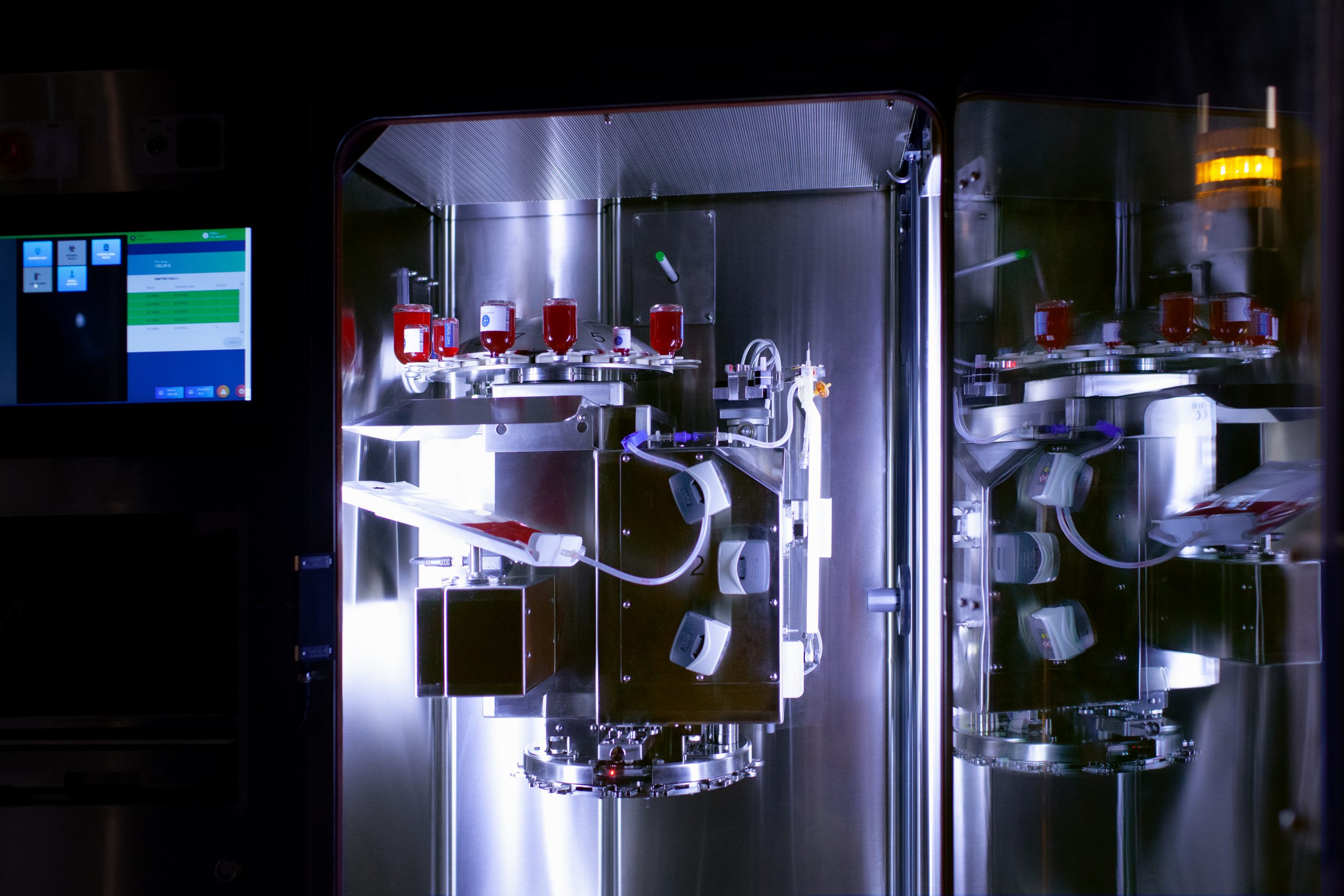

Compounding automation: a tailor made experience

Antiblastic compounding is a complex world. It is restricted by regulations, pressured by tight deadlines, and ever-growing logistical complications. But ultimately, the goal is to deliver quality medications customised to treat cancer patients. With decades of combined Pharmacy Automation experience, our team will help you in your journey towards the future of antineoplastic compounding.

As is: analysis

Understanding the challenges of this unique high-risk environment, and appreciating the substantial differences among different compounding sites, our first step is always to analyse the pre-existing conditions: our team of experts will gather all relevant information on your workflow and needs. Some of the information that our team will be analysing include your drug formulary, the final containers in use at your facilities, your current workforce and equipment, and the prescription software in use.

To be: improvement

Next, our Pharmacy consultants and automation experts will find any optimization opportunities and will provide an overview of the improved scenario once automation is adopted, including information on the quota of antiblastic preparations that can be compounded automatically by Pharmoduct at your site and the estimated yearly throughput.

An interconnected solution

With our strong expertise in software intercommunication, we will also provide integration specifications to ensure a seamless experience from dose prescription to drug delivery, aiming at a paperless, safe and completely monitorable workflow, through an interface with any third-party software.

No structural changes required

Before the implementation, we will perform one or more on-site visits so that our implementation experts verify that your cleanroom is suitable for Pharmoduct. Generally, Pharmoduct has a small footprint and turnkey design, and we are sure our device will fit into most ISO-regulated environments.

Easy implementation

The installation and implementation phase will take place over a few weeks: our technicians will also perform operational qualification protocols at your site to ensure that your new workflow is safe and compliant with Good Manufacturing Practices, with the minimum impact on your productivity to ensure continuity of service at your compounding site.

Training and support

In parallel with the installation and implementation phase, we will train your technicians to use Pharmoduct. Then, during the go-live phase and for a few weeks, our product specialists will continue to support you, providing additional training on the job.

What happens next?

From this point onward, our team will continue to monitor the usage of Pharmoduct at your facility throughout the years. Our team support you in implementing new drugs when required, providing mentoring and support, and finally, recommending improvements.

Are you ready to start your journey towards an automated compounding workflow? Get in touch today.